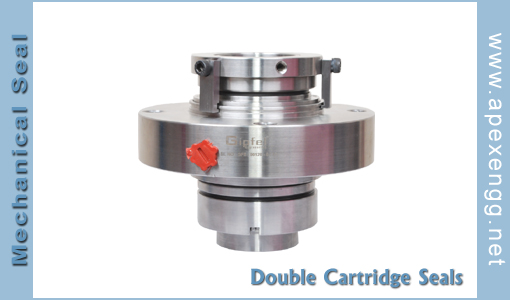

Double Cartridge Seal

| Application | Applied In Sealing High Corrosion Media, Alcohol Processing Industries, Pulp And Paper Industries, Petrochemical Plants, Nuclear Plants, Mixers, Steel Making Plants, Biochemistry, Petroleum Refineries, Oil Refineries, General Chemicals, Light Hydrocarbons, Foodstuff Processing, Chemical Processing, Pharmaceuticals, Power Generation, Main Oil Pipeline Pumps, Chemical Process Pumps , High Pressure Pumps, Water Injection Pumps, Boiler Feed Water Pumps, Sludge & Syrup Pumps, Vertical Pumps, Sewage Treatment Systems, Wastewater Treatment, Clinker Grinders, Paint, Abrasive Liquid In Grinding Mills And General Rotary Equipments |

| Material | Faces : Silicon Carbide, Tungsten Carbide, Stallite, Cr. Steel, Carbon, Ceramic |

| Elastomers : Viton, Aflas, Chemraz, Kalrez, Hiflour, T.V, NBR, EPDM, PTFE, EncapsulatedGFT, FFKM, TRP & Other | |

| Metal Parts : S.S.304, S.S. 316, 904L, Hastalloy-C, Alloy-20, Titanium, C-276 & Monel | |

| Operating Limits | Diameter : Up To 150mm |

| Pressure : Up To 55 Bars | |

| Temperature : Up To +300° C | |

| Velocity : Up To 25 M/S |

APEX ENGINEERING : Products Range

Chemical Process Pumps :

Centrifugal Metallic Pump Centrifugal Non Metallic Pump

Centrifugal Non Metallic Pump

Centrifugal Mono block Pump

Centrifugal Mono block Pump

Centrifugal Self Priming Pump

Centrifugal Self Priming Pump

Vertical Pump

Vertical Pump

Mechanical Seals :

Single Spring Seal Multi Spring Seal

Multi Spring Seal

Teflon Bellow Seal

Teflon Bellow Seal

Metal Bellow Seal

Metal Bellow Seal

Rubber Bellow Seal

Rubber Bellow Seal

Split Mechanical Seal

Split Mechanical Seal

Dry Running Mechanical Seal High Pressure Mechanical Seal

High Pressure Mechanical Seal

Double Cartridge Seals

Double Cartridge Seals

Agitator Mechanical Seal

Agitator Mechanical Seal

Centrifugal Metallic Pump

Centrifugal Non Metallic Pump

Centrifugal Non Metallic Pump

Centrifugal Mono block Pump

Centrifugal Mono block Pump

Centrifugal Self Priming Pump

Centrifugal Self Priming Pump

Vertical Pump

Vertical PumpMechanical Seals :

Single Spring Seal

Multi Spring Seal

Multi Spring Seal

Teflon Bellow Seal

Teflon Bellow Seal

Metal Bellow Seal

Metal Bellow Seal

Rubber Bellow Seal

Rubber Bellow Seal

Split Mechanical Seal

Split Mechanical SealDry Running Mechanical Seal

High Pressure Mechanical Seal

High Pressure Mechanical Seal

Double Cartridge Seals

Double Cartridge Seals

Agitator Mechanical Seal

Agitator Mechanical Seal